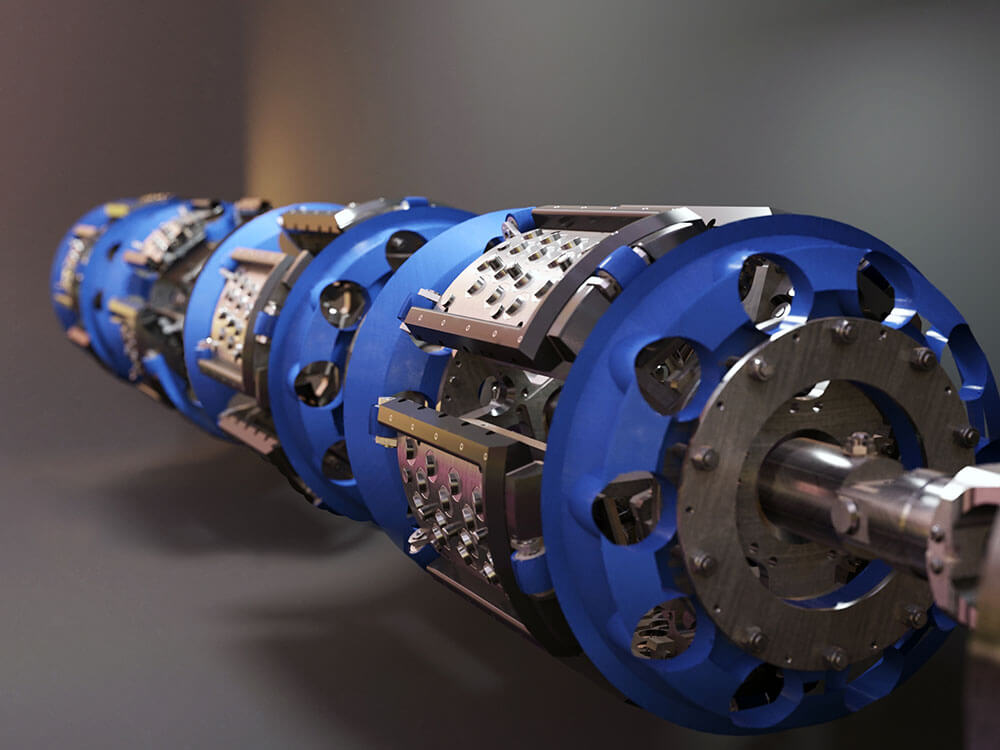

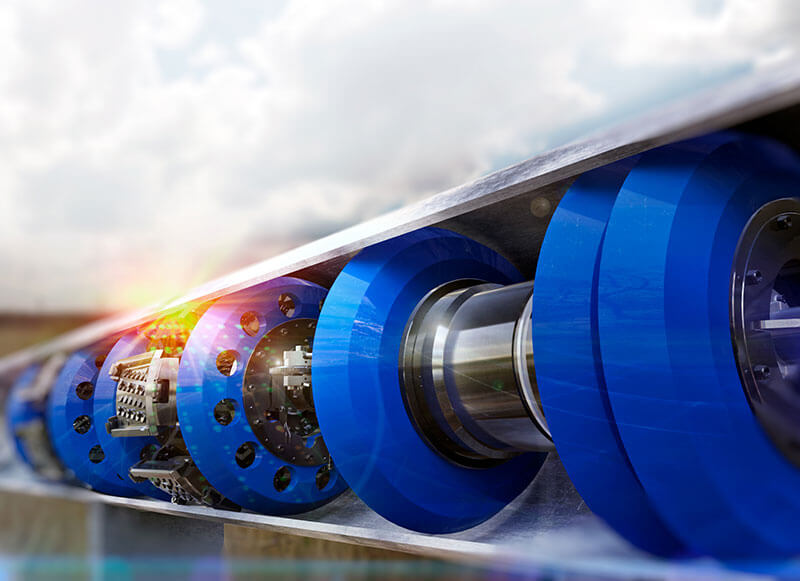

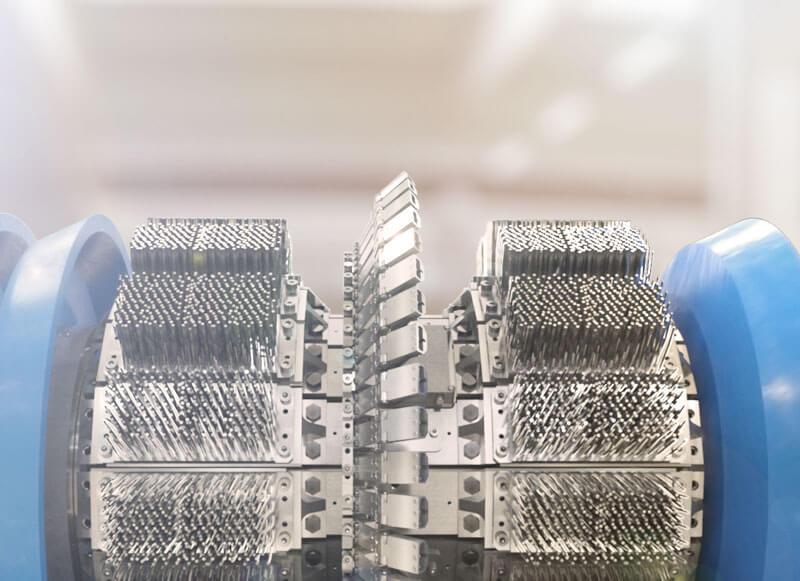

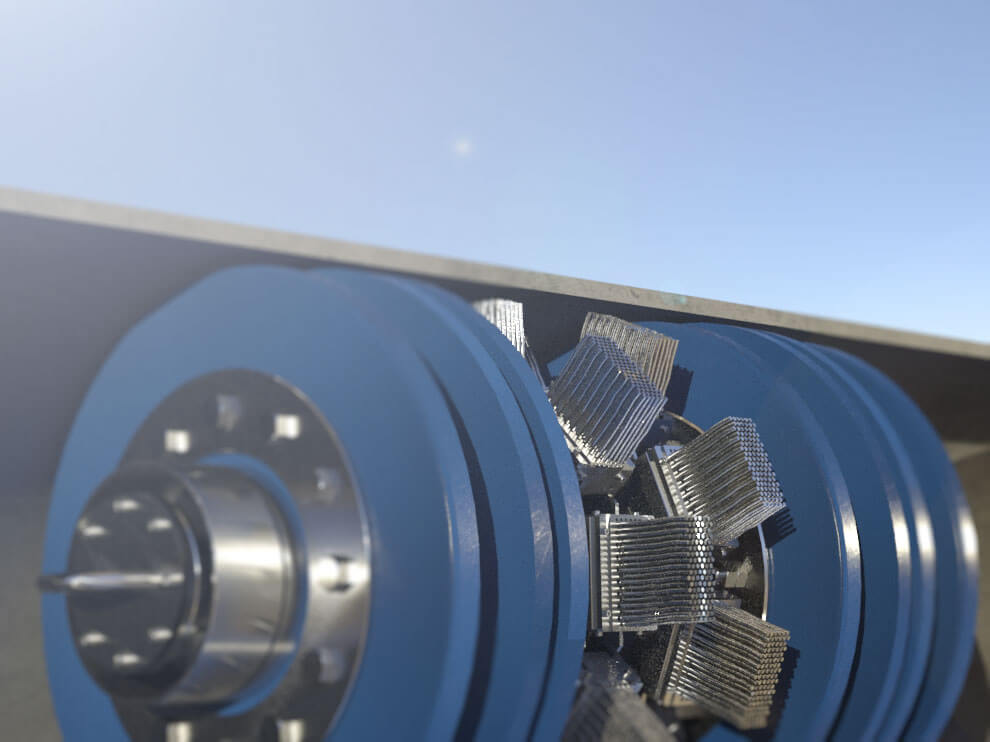

Our tools have a modular design which is an approach that subdivides a system into smaller parts called modules that can be independently created and then used in different systems. | Our tool design uses the same UTCD sensor path for tools ranging between 12” to 32” with both longitudinal and circumferential options. |

No need for a liquid couplant and a unique added value over UTCD method. | A unique added value over the Direct Voltage Gradient (DCVG) method. The testing data collected by the EMAT confirms to the POF 2016 and the Tool Performance Specifications. |

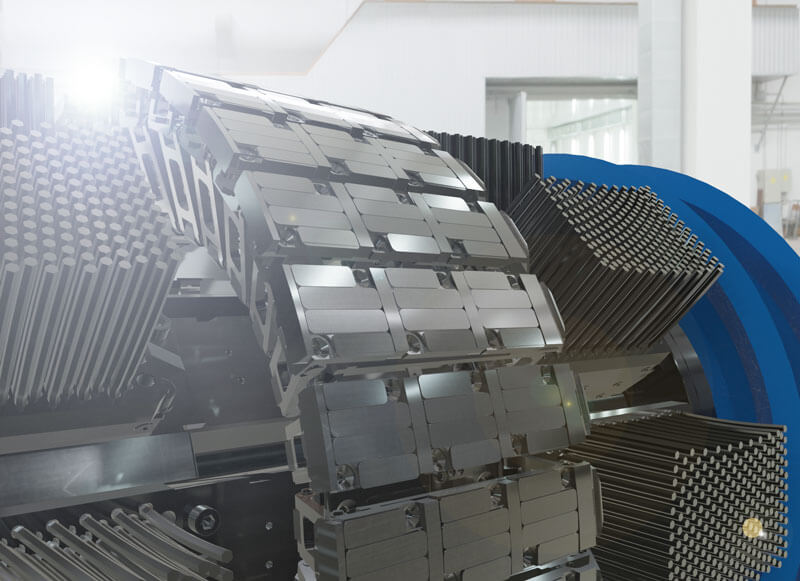

Very few inspection companies provide UT In-Line Inspection services, and PIPECARE is among them. | Equipped with arrays of UT transducers covering 360° of the pipe circumference and thus the measurement system not only measures the remaining pipe wall but also sizing the length and width of anomalies. |

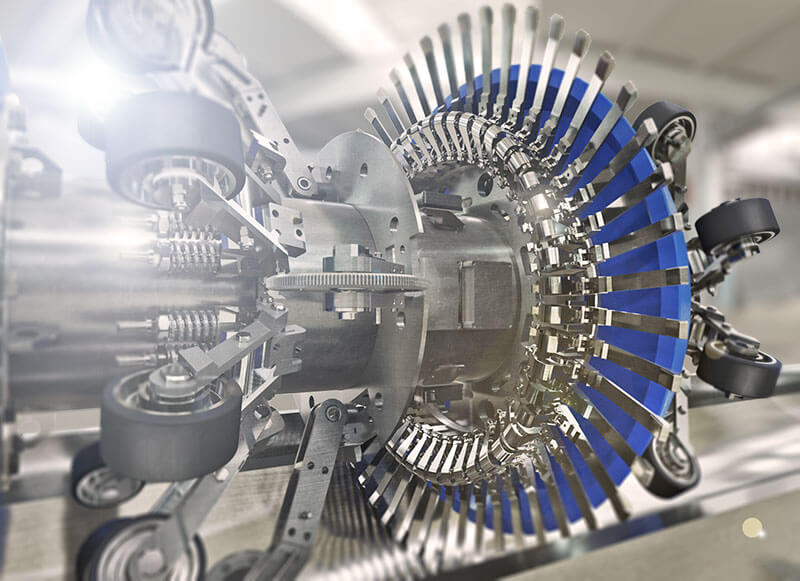

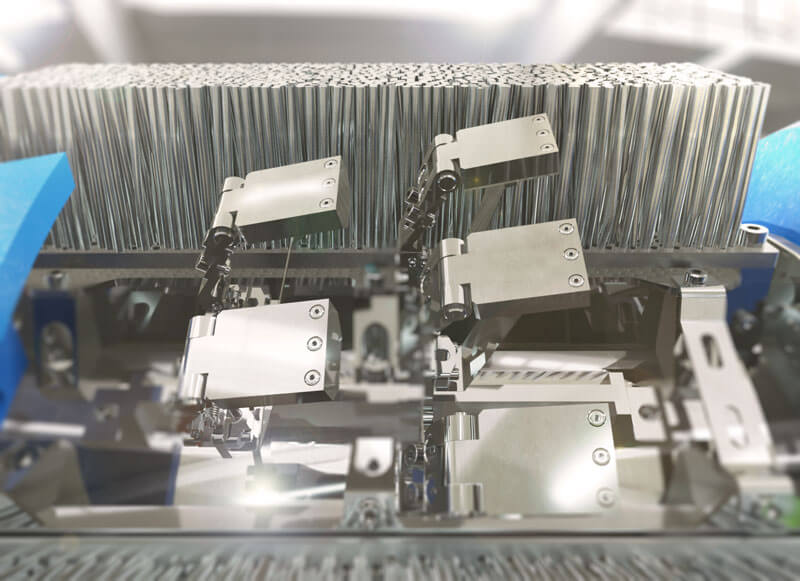

We equip measurement arms with individual sensors independent from each other and each having a separate signal channel. | Mechanical measurement arms are in direct contact with the pipe wall and cover 360° of pipe circumference. | We can do ILI tool run comparisons that are highly recommended for baseline surveys. This is a perfect reference system for future inspection data synchronization. |

Reliable detection and sizing of metal loss – and narrow longitudinally-oriented crack-like anomalies. | Tools can negotiate 1.5D radius bends and magnetize heavy wall thickness. | TFI tool can be run as a standalone tool or in combination with other inspection technologies, such as MFL, UT, geometry, and mapping. |

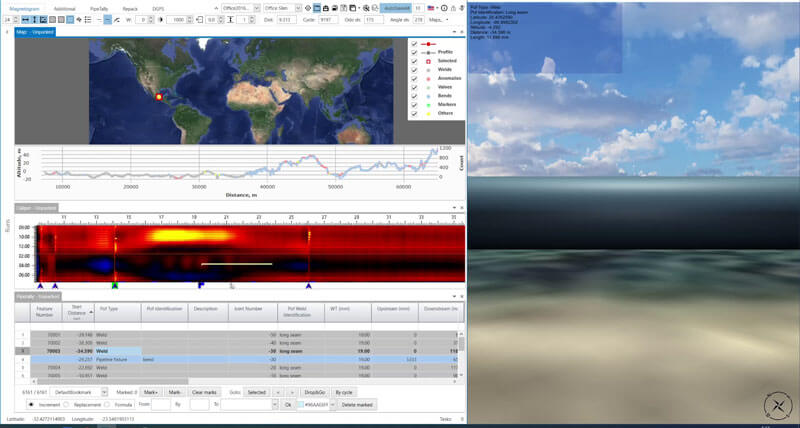

Providing pipeline operators with pipeline metal loss information helping to improve safety, environmental, and economic performance. | Latest generation MFL Tools – “True High-Resolution” systems. These tools are equipped with measurement systems based on the highest resolution. | We are a member of ComplyWorks and ISNetworld and have passed the required qualifications to be an accredited member. | Our integrity support helps to avoid production and consequential losses caused by pipeline failures. |

Our cleaning and gauging pigs can be equipped with low-frequency transmitters. | Mechanical measurement arms are in direct contact with the pipe wall and cover 360° of pipe circumference. |

Presents the integrity deterioration now and at any time in the future | Indicates the time available and when time is running out for efficient mitigation | Provides intelligent dashboards for improved decision making | Gives options for better optimization of rehabilitation, maintenance, and repairs |