SERVICES MENU

ONE OF THE FEW UT INSPECTION PROVIDERS IN THE WORLD

Ultrasonic In-Line Inspection is using an ultrasonic echo signal to measure the pipe wall thickness, detecting any variations from the nominal values.

In intelligent pigging applications, these high-frequency radial signals are emitted by UT transducers perpendicularly to a pipe wall. These signals produce two significant echoes – from the inner surface and the outer surface of a pipe wall. We detect the anomalies through the registered difference between periods of receiving the echo signals from a healthy pipe (nominal values) and pipe wall with metal loss or any inhomogeneity.

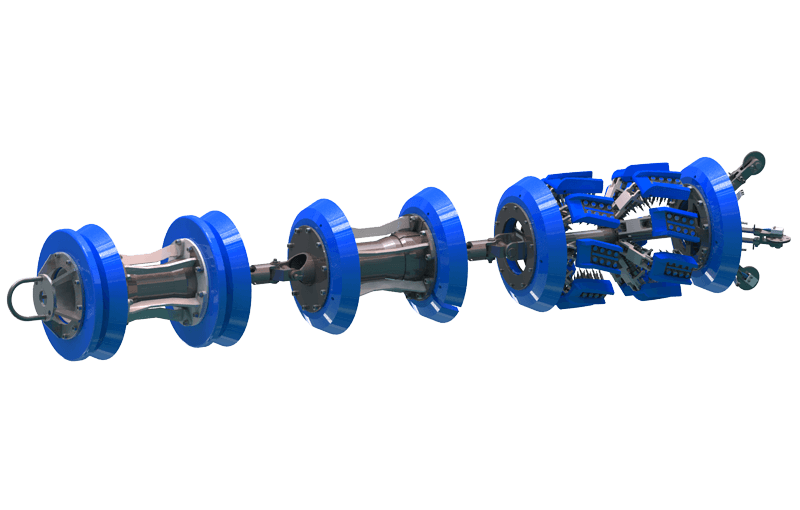

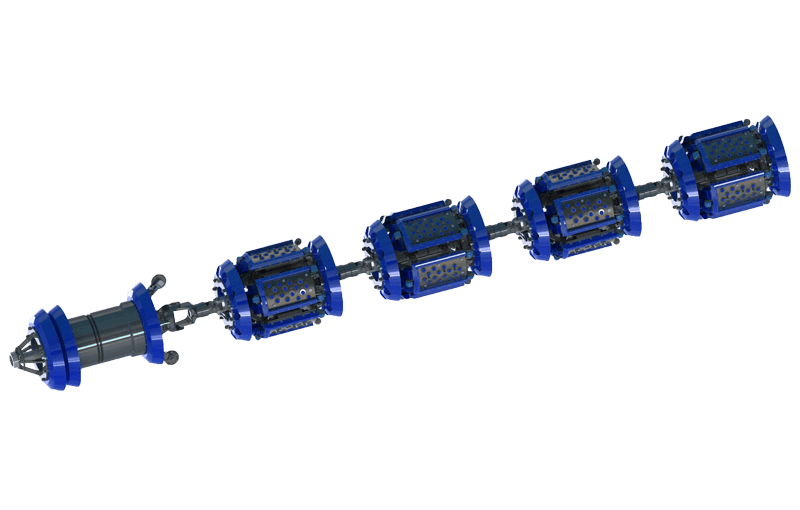

PIPECARE ultrasonic metal loss inspection tools work based on the direct measurement principle to ensure quantitative wall thickness measurements, superior detection, and sizing of metal loss anomalies, laminations, and inclusions.

In intelligent pigging applications, these high-frequency radial signals are emitted by UT transducers perpendicularly to a pipe wall. These signals produce two significant echoes – from the inner surface and the outer surface of a pipe wall. We detect the anomalies through the registered difference between periods of receiving the echo signals from a healthy pipe (nominal values) and pipe wall with metal loss or any inhomogeneity.

PIPECARE ultrasonic metal loss inspection tools work based on the direct measurement principle to ensure quantitative wall thickness measurements, superior detection, and sizing of metal loss anomalies, laminations, and inclusions.

UT INSPECTION TECHNOLOGY ADVANTAGES

We have equipped our inspection tools with arrays of UT transducers covering 360° of a pipe wall, and thus the measurement system not only measures the remaining pipe wall but also sizing the length and width of anomalies.

UT inspection technology ensures the perfect sizing accuracy and metal loss depth – better than any other technology. Also, besides sizing and detection of general metal loss anomalies, this is the only technology providing a reliable measurement of mid-wall laminations.

UT inspection technology ensures the perfect sizing accuracy and metal loss depth – better than any other technology. Also, besides sizing and detection of general metal loss anomalies, this is the only technology providing a reliable measurement of mid-wall laminations.

PIPECARE UT TOOLS SPECIFICATIONS

| Description | Value |

|---|---|

| Tool Sizes | 2’’ to 56" |

| Pipeline product | Liquids |

| Operating pressure range | 0 to 12 MPa |

| Operating temperature range | -20 to +85° C |

| Wall thickness range | 4 to 32 mm |

| Tool velocity range | 0.2 to 2.0 m/sec |

| Min. pipeline bend radius | 1.5D |

| Min. passage bore | 80-85% of OD |

DETECTION AND SIZING

| Description | General Metal Loss | Pitting | Axial Grooving | Circumferential Grooving |

|---|---|---|---|---|

| Depth at POD | 1 mm | 1 mm | 1 mm | 1 mm |

| Depth sizing | +/- 0.4 mm | +/- 0.4 mm | +/- 0.4 mm | +/- 0.4 mm |

| Width sizing | +/- 5 mm | +/- 5 mm | +/- 5 mm | +/- 5 mm |

| Length sizing | +/- 4 mm | +/- 4 mm | +/- 4 mm | +/- 4 mm |

LOCATION ACCURACY

| Description | Value |

|---|---|

| Axial position from closest weld at 90% certainty | +/- 0.15m |

| Accuracy of distance from pig trap valve at 90% certainty | +/- 0.2% |

| Accuracy of circumferential position at 90% certainty | +/- 10° |