SERVICES MENU

BEST DETECTION & PERFORMANCE ON CRACK-LIKE ANOMALIES

Longitudinal weld anomalies and narrow axial internal and external corrosion can pose a severe integrity threat to pipelines. Conventional MFL tools that apply the magnetic field in the axial direction do not provide reliable detection and sizing of such anomalies.

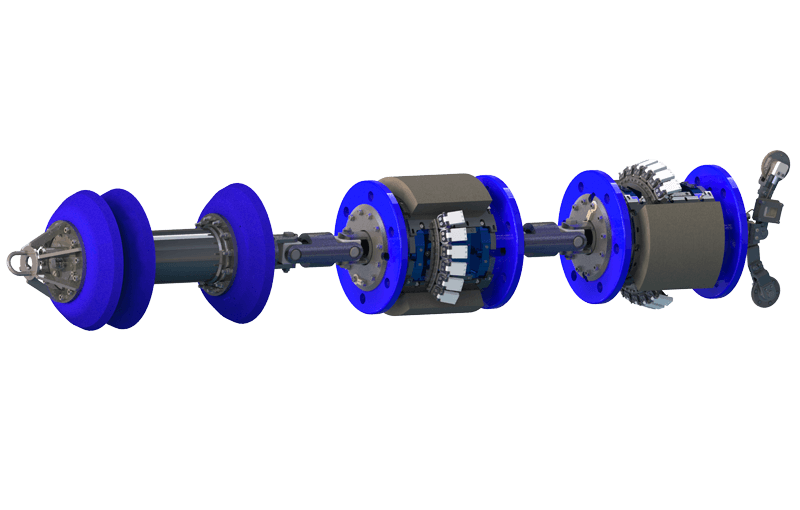

PIPECARE Transverse Field Inspection technology is also magnetic flux leakage based. However, magnetizer sections installed in the inspection tool induce a flux field in the circumferential direction. The proven design and high magnetization of the TFI tools coupled with an extra-high circumferential resolution provide reliable detection and sizing of narrow longitudinally-oriented metal loss anomalies.

This magnetizer system design ensures detection and sizing of general type metal loss anomalies, the same as conventional MFL tools. However, it is also specially developed for the measurement of longitudinally oriented anomalies such as tunnel corrosion, longitudinal weld anomalies.

We run our PIPECARE TFI tools as stand-alone tools. We can combine it with other inspection technologies, such as MFL, UT, geometry, and mapping.

PIPECARE Transverse Field Inspection technology is also magnetic flux leakage based. However, magnetizer sections installed in the inspection tool induce a flux field in the circumferential direction. The proven design and high magnetization of the TFI tools coupled with an extra-high circumferential resolution provide reliable detection and sizing of narrow longitudinally-oriented metal loss anomalies.

This magnetizer system design ensures detection and sizing of general type metal loss anomalies, the same as conventional MFL tools. However, it is also specially developed for the measurement of longitudinally oriented anomalies such as tunnel corrosion, longitudinal weld anomalies.

We run our PIPECARE TFI tools as stand-alone tools. We can combine it with other inspection technologies, such as MFL, UT, geometry, and mapping.

TFI ensures detection and sizing on certain anomalies that conventional axial MFL technology face with difficulties.

Our TFI tools can optionally be equipped with IMUs to carry out pipeline mapping simultaneously.

TFI has the highest effective resolution, both axial and circumferential, ensuring the best sizing accuracy within the natural limitations of magnetic inspection technology.

PIPECARE TOOL SPECIFICATIONS

| Description | Value |

|---|---|

| Tool sizes | 4" to 56" |

| Pipeline product | All Media (gas, liquids, multiphase) |

| Operating pressure range | 0 to 12 MPa |

| Operating temperature range | -20 to +85° C |

| Wall thickness range | 3-20 mm |

| Tool velocity range | 0.2 – 4.0 m/sec |

| Min. pipeline bend radius | 1.5D (8’’ and above) |

| Min. passage bore | 80-85% of OD |

| Detection & Sizing | General Metal Loss | Pitting | Axial Grooving | Axial Slotting |

|---|---|---|---|---|

| Depth at POD 90% | 0.1t | 0.15t | 0.1t | 0.15t |

| Depth sizing accuracy at 80% certainty | +/- 0.1t | +/- 0.15t | +/- 0.1t | +/- 0.15t |

| Width sizing accuracy at 80% certainty | +/- 15 mm | +/- 15 mm | +/- 15 mm | +/- 15 mm |

| Length sizing accuracy at 80% certainty | +/- 15 mm | +/- 15 mm | +/- 15 mm | +/- 15 mm |

| Location Accuracy | Value |

|---|---|

| Tool sizes | 6’’ to 24’’ |

| Accuracy of distance from pig trap valve at 90% certainty | +/- 0.2% |

| Accuracy of circumferential position at 90% certainty | +/- 10° |