SERVICES MENU

INSPECTION & ACCURATE CRACK DETECTION

Upstream pipelines carrying multiphase fluids, slurry, crude, condensate, and raw natural gas often at elevated temperatures are more prone to cracks and crack-like threats than downstream pipelines that deliver refined petroleum products and processed pipeline quality gas. Axial cracking (cracks oriented along pipeline axis) or crack propagation occurs due to hoop-stress generated in pipe wall resulting from operating pressure contained in the pipeline.

Circumferential cracking (cracks oriented perpendicular to pipeline axis) or crack propagation occurs due to bending and/or longitudinal stresses caused due to geotechnical movements in soil or operational extremities. However, initiation of all such cracks require a structural anomaly created in the pipe wall at any stage:

• During pipe manufacture in pipe mill or transportation (causing seam weld cracks, indentation, notches)

• During pipeline construction as a result of fabrication or welding (causing shrinkage crack in the vicinity of girth weld, lack of fusion, hook cracks, gouging)

• During pipeline operation due to mechanical stress or damage (causing fatigue cracks)

• With time due to corrosion (whether galvanic, process-related or environment-related)

PIPECARE provides recommendations to the client to ensure prudent QA/QC procedures that minimize the creation of such structural anomalies during line pipe procurement and pipeline construction. Once a pipeline is commissioned ILI provides reliable means to identify the formation or propagation of such cracks or crack-like features before they become high risk for pipeline integrity.

Ultrasonic Crack Detection (UTCD) has been developed based on the basic principle of wall thickness measurement of pipelines through the use of Piezoelectric transducers – Piezoelectric crystals undergo a repeated change in size and shape with the application of AC voltage causing oscillation and generation of ultrasonic sound frequency.

These signals require a single-phase liquid medium between the transducer and pipe wall to filter noise during pulse-echo operation. For quickly scanning of a pipeline for wall thickness, a number of such transducers are mounted on an ILI tool perpendicular to the pipe wall surface. The ultrasonic pulse generated by the transducer is partially reflected by the inner pipe wall and partially reflected by the outer pipe wall thus causing a time differential for the return path of two echoes.

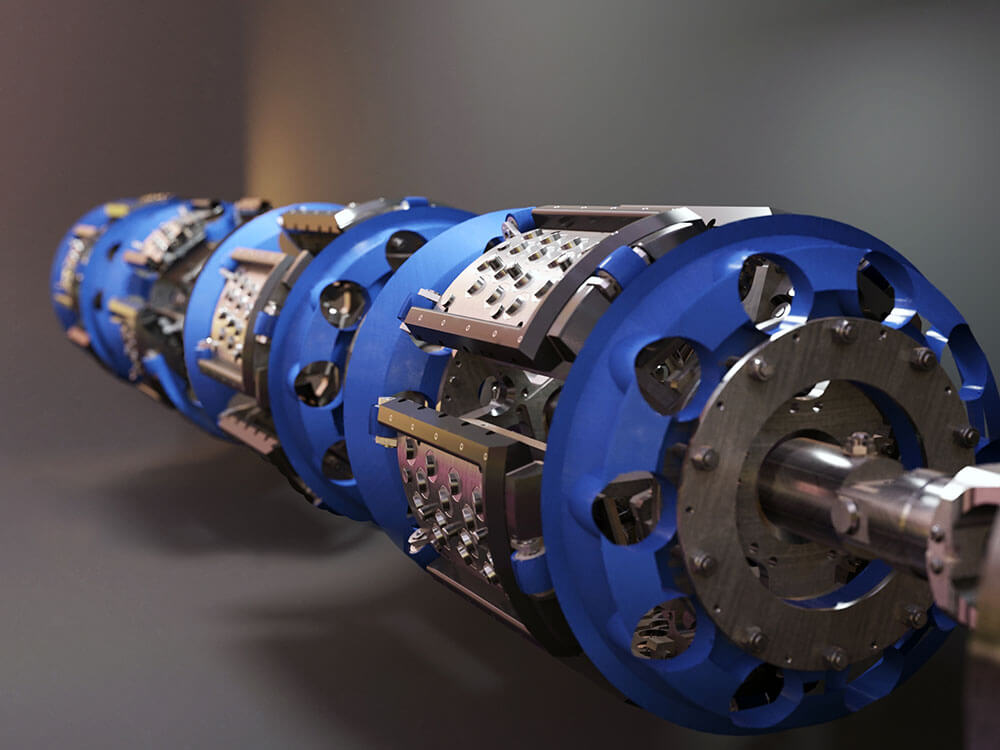

PIPECARE developed its UTCD tool based on pulse-echo UT with maximum sensor spacing at 4mm for circumferential as well as longitudinal crack detection. This means that our UTCD tool provides unmatched resolution and the highest possible probability of crack (and metal anomalies) detection in the market for a single ILI run.

PIPECARE’s high-resolution UTCD tool is field configurable to switch from longitudinal crack detection to circumferential crack detection. Consolidation of field data for successive runs (one each for longitudinal and circumferential crack detection) provides a better evaluation of results. Through the use of our proprietary algorithm, acquired high-resolution data generates superior capability for crack sizing and shape determination. This additionally means that PIPECARE is better placed to serve its customers for their ILI requirements related to pipeline crack detection and associated anomalies in a more cost-effective way.

UTCD has a high probability of detection (POI>90%) for internal and external cracks/crack-like features. It can be configured to detect longitudinal or circumferential crack anomalies. UTCD carries several ultrasonic transducers for wall thickness recording to support accurate crack depth sizing. The tool resolution is up to 2m/s velocity, and its performance specification is in full compliance with POF 2016 and the latest ATEX code.

Circumferential cracking (cracks oriented perpendicular to pipeline axis) or crack propagation occurs due to bending and/or longitudinal stresses caused due to geotechnical movements in soil or operational extremities. However, initiation of all such cracks require a structural anomaly created in the pipe wall at any stage:

• During pipe manufacture in pipe mill or transportation (causing seam weld cracks, indentation, notches)

• During pipeline construction as a result of fabrication or welding (causing shrinkage crack in the vicinity of girth weld, lack of fusion, hook cracks, gouging)

• During pipeline operation due to mechanical stress or damage (causing fatigue cracks)

• With time due to corrosion (whether galvanic, process-related or environment-related)

PIPECARE provides recommendations to the client to ensure prudent QA/QC procedures that minimize the creation of such structural anomalies during line pipe procurement and pipeline construction. Once a pipeline is commissioned ILI provides reliable means to identify the formation or propagation of such cracks or crack-like features before they become high risk for pipeline integrity.

Ultrasonic Crack Detection (UTCD) has been developed based on the basic principle of wall thickness measurement of pipelines through the use of Piezoelectric transducers – Piezoelectric crystals undergo a repeated change in size and shape with the application of AC voltage causing oscillation and generation of ultrasonic sound frequency.

These signals require a single-phase liquid medium between the transducer and pipe wall to filter noise during pulse-echo operation. For quickly scanning of a pipeline for wall thickness, a number of such transducers are mounted on an ILI tool perpendicular to the pipe wall surface. The ultrasonic pulse generated by the transducer is partially reflected by the inner pipe wall and partially reflected by the outer pipe wall thus causing a time differential for the return path of two echoes.

PIPECARE developed its UTCD tool based on pulse-echo UT with maximum sensor spacing at 4mm for circumferential as well as longitudinal crack detection. This means that our UTCD tool provides unmatched resolution and the highest possible probability of crack (and metal anomalies) detection in the market for a single ILI run.

PIPECARE’s high-resolution UTCD tool is field configurable to switch from longitudinal crack detection to circumferential crack detection. Consolidation of field data for successive runs (one each for longitudinal and circumferential crack detection) provides a better evaluation of results. Through the use of our proprietary algorithm, acquired high-resolution data generates superior capability for crack sizing and shape determination. This additionally means that PIPECARE is better placed to serve its customers for their ILI requirements related to pipeline crack detection and associated anomalies in a more cost-effective way.

UTCD has a high probability of detection (POI>90%) for internal and external cracks/crack-like features. It can be configured to detect longitudinal or circumferential crack anomalies. UTCD carries several ultrasonic transducers for wall thickness recording to support accurate crack depth sizing. The tool resolution is up to 2m/s velocity, and its performance specification is in full compliance with POF 2016 and the latest ATEX code.

| General Specifications | |

|---|---|

| Tool inspection technology | Pulse-echo UT |

| Tool inspection speed range, m/sec | 0.2 – 2.2 |

| Maximum sampling rate, time based, ms | 1.3 |

| Wall thickness range, mm | 4 – 25 |

| Maximum circumferential sensor spacing, mm | 4 mm |