SERVICES MENU

LOCATING GEOMETRY DEVIATIONS

In-Line Inspection allows pipeline operators to have better information on the condition of their pipeline systems and develop adequate maintenance and repair programs. Adopting a proactive approach to addressing integrity threats enables pipeline operators to avoid production and consequential losses caused by pipeline failures.

It is an industry common knowledge that the primary threat to pipeline integrity is corrosion growth and growth of cracking anomalies. However, mechanical deformations can cause accelerated growth of cracking. Geometry features combined with corrosion can be a severe threat to pipeline integrity. These threats are difficult to assess with existing models or practices.

Significant reductions of pipeline circular shape can negatively affect the flow of product and cause excessive consumption of power required for product transportation. It is vitally important to locate such geometry deviations on any pipeline.

It is an industry common knowledge that the primary threat to pipeline integrity is corrosion growth and growth of cracking anomalies. However, mechanical deformations can cause accelerated growth of cracking. Geometry features combined with corrosion can be a severe threat to pipeline integrity. These threats are difficult to assess with existing models or practices.

Significant reductions of pipeline circular shape can negatively affect the flow of product and cause excessive consumption of power required for product transportation. It is vitally important to locate such geometry deviations on any pipeline.

CALIPER INSPECTION TECHNOLOGY

A FLEXIBLE SOLUTION FOR PIPELINES

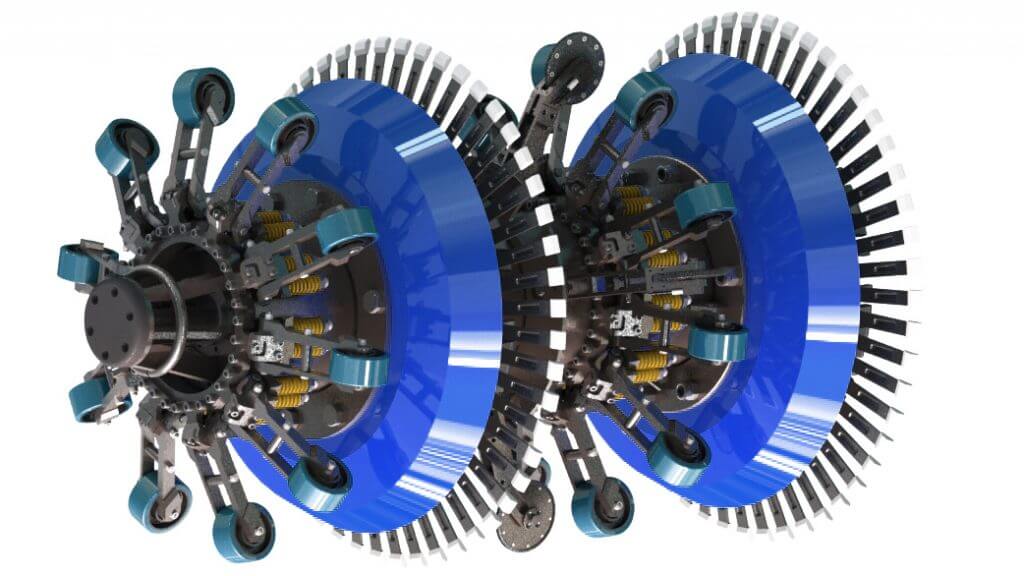

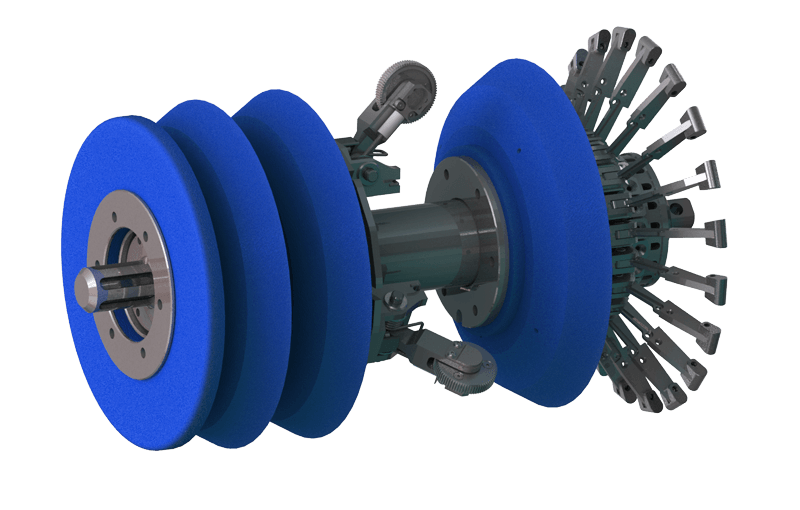

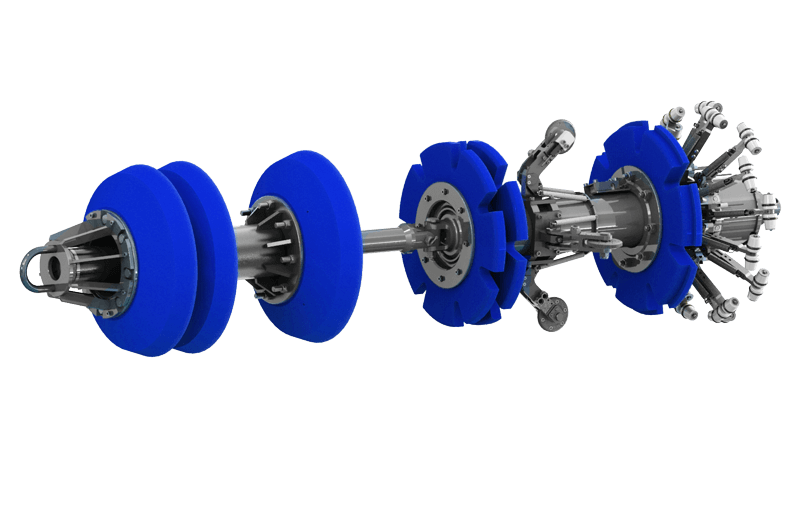

We provide geometry inspection services using caliper technology on all pipeline sizes of the oil and gas industry supported by a large fleet of Caliper Geometry inspection tools.

DETECTION AND SIZING SPECIFICATIONS

| Features and anomalies |

|---|

| Valves, flanges, welds, tees, taps, bends |

| Dents, buckles, wrinkles, ovalities, ID changes |

| Detection and sizing specifications (at 80% certainty) | Value |

|---|---|

| Dents detection threshold | 1.5% of OD |

| Depth sizing accuracy | +/- 1.5% of OD |

| Ovality detection threshold | 2% of OD |

| Ovality sizing accuracy | 2% of OD |

| Probability of detection | 95% |

| Location accuracy (at 90% certainty) | Value |

|---|---|

| Axial position from closest weld | +/- 0.15 m |

| Accuracy of distance from pig trap valve | +/- 0.2% |

| Accuracy of circumferential position | +/- 10° |