SERVICES MENU

RELIABLE, SIMPLE, AND EFFICIENT

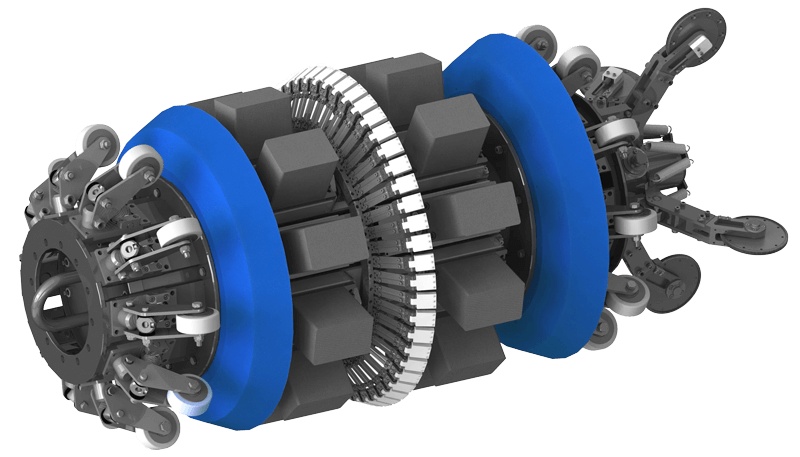

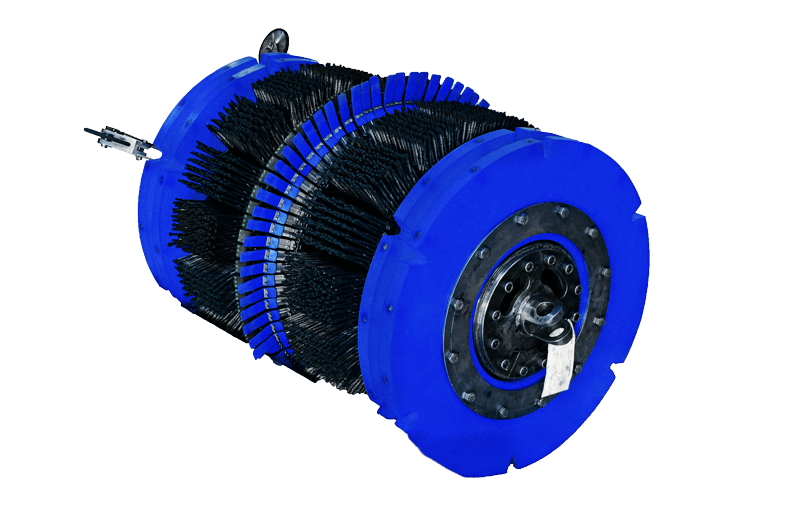

We use MFL for detection and sizing of general corrosion and other metal loss anomalies, especially circumferentially oriented. MFL tools have limited capability of detection and sizing of girth weld anomalies. Over the years several generations of the MFL systems have been subsequently developed involving significant improvement of their performance specifications.

FLEXIBLE SOLUTIONS

To clients who operate pipelines that are difficult to inspect, we offer our customized solutions for the following pipeline conditions:

- Low pressure

- Low flow

- High temperature

- Heavy wall thickness

- Sour product

- No pig traps or single-point entry

PIPECARE MFL TOOL SPECIFICATIONS

| Description | Value |

|---|---|

| Tool sizes | 2’’ to 56" |

| Pipeline product | All Media (gas, liquids, multiphase) |

| Operating pressure range | 1 to 12 MPa |

| Operating temperature range | -20 to 85° C |

| Wall thickness range | 3 - 25.4 mm |

| Tool velocity range | 0.2 – 5.0 m/sec |

| Min. pipeline bend radius | 1.5D (6’’ and above) |

| Min. passage bore | 80-85% of OD |

DETECTION & SIZING

| Description | General Metal Loss | Pitting | Axial Grooving | Circumferential Grooving |

|---|---|---|---|---|

| Depth at POD 90% | 0.1t | 0.1t | 0.1t | 0.1t |

| Depth sizing accuracy at 80% certainty | +/- 0.1t | +/- 0.13t | +/- 0.15t | +/- 0.1t |

| Width sizing accuracy at 80% certainty | +/- 15 mm | +/- 12 mm | +/- 12 mm | +/- 15 mm |

| Length sizing accuracy at 80% certainty | +/- 10 mm | +/- 10 mm | +/- 15 mm | +/-10 mm |

LOCATION ACCURACY

| Description | Value |

|---|---|

| Axial position from closest weld at 90% certainty | +/- 0.15 m |

| Accuracy of distance from pig trap valve at 90% certainty | +/- 0.2% |

| Accuracy of circumferential position at 90% certainty | +/- 10° |

PIPECARE has an extensive record of successfully deploying customized solutions for unpiggable pipelines worldwide. Available for pipeline diameters from 2” to 56”.