SERVICES MENU

THERE IS NO PIPELINE THAT CANNOT BE CLEANED.

Pipelines must be cleaned for several reasons: to maintain product transport efficiency, to ensure the purity of the product, and to successfully run In-Line Inspection tools.

Debris and sludge may seriously affect the process by reducing the effective pipeline cross-section. It can lead to a higher consumption of energy required to propel the same amount of product through the same line.

In case a pipeline is not regularly cleaned, the purity of the oil or gas is affected. It may consequently damage the downstream facilities and processes.

PIPECARE develops specific cleaning programs adapted to particular lines based on the product and debris analysis, vast experience, and best industry practices.

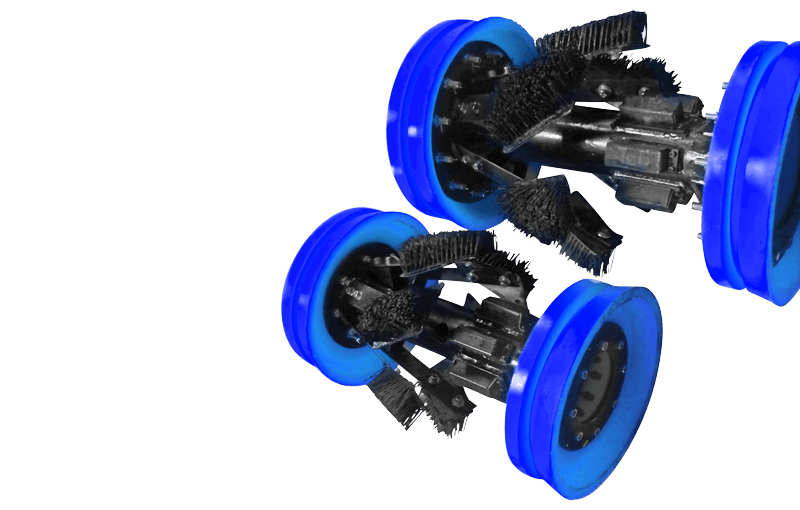

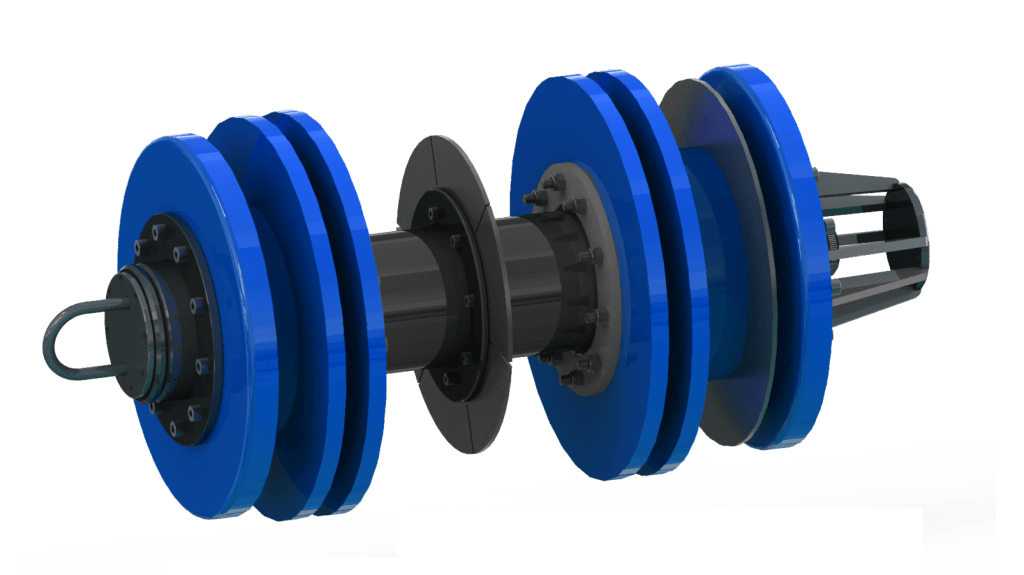

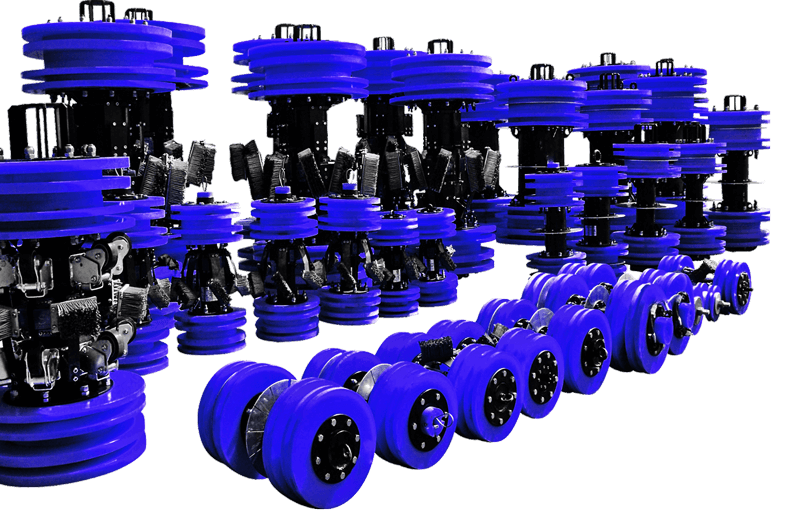

The cleaning operations we perform are tailored to particular project conditions. Our equipment is designed and built to remove specific types of sludge, debris, and dust that can be found in a pipeline.

Debris and sludge may seriously affect the process by reducing the effective pipeline cross-section. It can lead to a higher consumption of energy required to propel the same amount of product through the same line.

In case a pipeline is not regularly cleaned, the purity of the oil or gas is affected. It may consequently damage the downstream facilities and processes.

PIPECARE develops specific cleaning programs adapted to particular lines based on the product and debris analysis, vast experience, and best industry practices.

The cleaning operations we perform are tailored to particular project conditions. Our equipment is designed and built to remove specific types of sludge, debris, and dust that can be found in a pipeline.

CLEANING CAMPAIGNS

PIPECARE offers pre-inspection and routine cleaning campaigns customized to the pipeline operator. We also clean water pipelines, mining pipelines, and pipelines with all standard products.

We have vast experience in cleaning oil pipelines with high wax content using specially developed de-waxing pigs. These pigs are equipped with polyurethane blades, steel scrapers, and other arrangements ensuring effective cutting and removing wax sediments.

We use a range of cleaning pigs with supporting wheels to shift the load from the cups and discs to ensure that the cleaning effect is preserved for the whole run duration.

We use an efficient and economical system to separate dust particles (down to 5 microns) from the gas without interruption of regular operations and even when a pig is in the line.