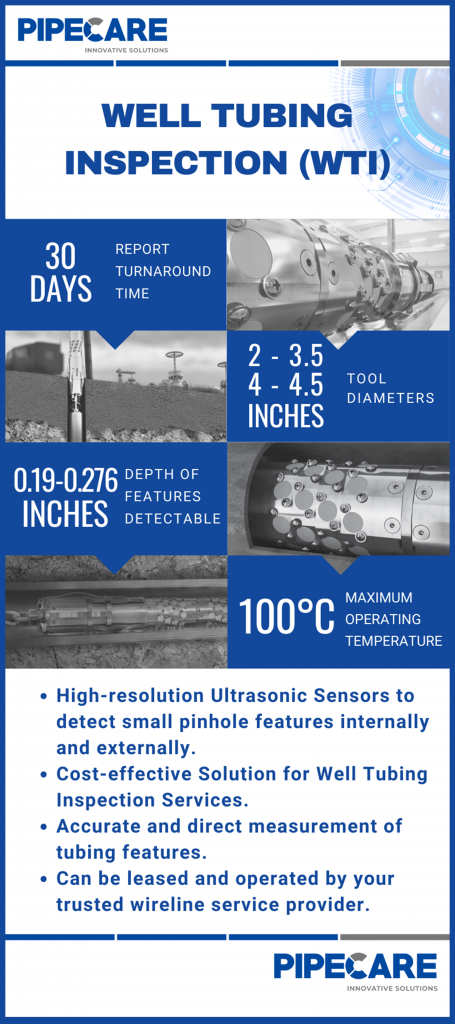

PIPECARE has long been known as the premium provider of gathering, transmission and distribution pipelines; popularly known as horizontal pipelines. Upon request, last year we developed an inspection service for detecting, sizing and locating small size deficiencies; internal and external pin holes in the top part of Well-Tubing of what is known as a vertical pipeline..

The technology is proven and cost-effective.

THE REQUEST

- Provide an UT type tool for the inspection of the top 900meters deep part of the well tubing.

- For the detection, sizing and locating of small diameter pin holes (0.078” – 0.118”).

- The well will be shut down and your trusted wireline provider will set a plug to hold a water column.

- The depth is the maximum capability for setting the plug for both pressure and temperature limitations (90bars and 90 degrees Celsius).

- The wireline provider will also lower the inspection tool in the well tubing .

PIPECARE SOLUTION

- We developed a super high resolution UT inspection tool for detecting, sizing and locating small diameter pin holes.

- Recommended Maximum operating pressure 100bar.

- Recommended Maximum operating temperature 100 degrees Celsius (212 Fahrenheit).

- A computes support program that enables instant reporting.

- Field technician for supervising the operations and provide answers to questions that may arise from the reported findings.

- The recommended limit is to inspect 1 to 2 wells per day.

What makes our downhole tubing solutions THE OPTIMAL CHOICE?

Perhaps the biggest and most common fear to well operators in regards to well tubing inspection is a stuck inspection tool, due to the challenges presented by the small diameter well tubing , its wall thicknesses, and its associated internal diameters, which can vary significantly due to manufacturing tolerances.

PIPECARE’s Ultrasonic Well Tubing Inspection technology has been designed specifically for nominal well tubing sizes 2 to 3.5 inch, and 4 to 4.5 inch diameters, and can inspect wall thicknesses from 0.19 to 0.276 inch (4.82 mm to 7.01 mm).

Another historical challenge to well tubing inspections is that the inspection has been typically limited to the These advantages, combined with the high-resolution ultrasonic capability to detect small diameter internal and external „pinholes”, make PIPECARE’s Well Tubing Inspection Service not only the optimal choice, but also the obvious choice.

Assessment procedures can detect loss or decrease in integrity in natural gas pipelines and recommend measures to prevent it. They use leak surveys, cathode protection systems effectiveness, or corrosion control reviews to provide the operators with relevant information regarding the integrity and pipeline safety condition.

Though pipeline inspection aims at detecting metal loss by measuring wall thickness, pipeline in-line inspection can also help in the following